Lws Environmental Protection Decanter Centrifuge for Sludge Dewatering

Product Application The LWS horizontal screw centrifuge is a new type of Three-phase horizontal screw centrifuge mainly

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | LWS |

| Pressure | Medium Pressure |

| Condition | New |

| Material | SS304 or SS316 L |

| Warranty | 12monthes |

| Machine Name | Lw Decanter Centrifuge for Sludge Dewatering |

| Lubrication Oil | Automatic Lubrication |

| Gear | Planet Gear |

| Transport Package | Wooden Cases |

| Specification | 2065*1050*800 |

| Trademark | Reyes |

| Origin | Zhejiang |

| HS Code | 8421192000 |

| Production Capacity | 500sets |

Product Description

Product Application

The LWS horizontal screw centrifuge is a new type of Three-phase horizontal screw centrifuge mainly suitable for three phase separation (oil- water- solid )of separation plant .

* Small horizontal screw centrifuge, with the characteristics of high separation factor, small processing capacity and high rotation speed, is mainly used in laboratories, food processing, pharmaceutical factories, and factories with oil-water solid phase separation requirements.

* The larger horizontal screw centrifuges, with two different types of length diameter ratio, high and short, can be selected according to the customer's requirements, widely used in the separation of papermaking, crude oil, printing and dyeing,pharmaceutical, chemical, food, fish oil, soybean protein, etc.

* Large scale horizontal screw centrifuges are mainly used in papermaking, printing and dyeing, pharmaceutical, chemical industry, drilling mud separation, deacidification of thermal power plant, particle powder, sewage treatment, water plant, monosodium glutamate plant, food processing plant, etc

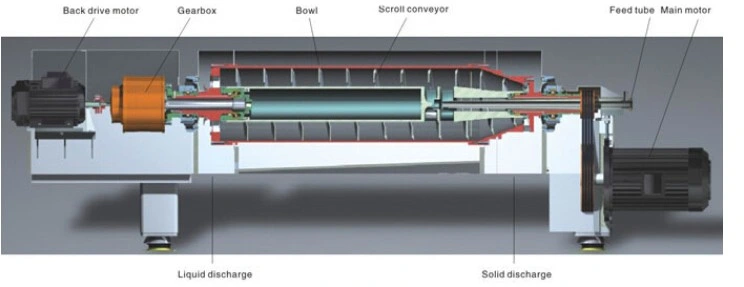

Working principle

Three-phase centrifuge principle: due to different materials in the light liquid - heavy liquid - insoluble solid proportion, the three-phase material by centrifugal force is not the same size, Insoluble solids are deposited into the inner wall (outermost) due to the maximum specific gravity of the centrifuge.

The light liquid phase is settled furthest from the inner wall of the drum because it is subjected to the least centrifugal force. heavy liquid phase in its middle, The insoluble solid phase is discharged from the solid phase outlet by a screw puller with relative differential speed to the drum.

The light, heavy liquid phase through the different structure of the machine within their respective separately, the heavy liquid discharge phase by centrifugal force, light liquid phase discharge by gravity , so as to lead the material three phase separation.Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Technical Paramter:

| Model | Dia mm | Ratio | Speedrpm | G force | Main Motor (Kw) | Auxiliary Motor (kW) | Capacity m3/h | Weightkg | Dimension(L×W×H)mm |

| LWS240×720 | 240 | 3 | 5000 | 3360 | 7.5~11 | 3~4 | 0.3~1.8 | 750 | 1900×1250×680 |

| LWS355×1460 | 355 | 4 | 3600 | 2576 | 15~22 | 4~5.5 | 2~10 | 1800 | 2270×1350×830 |

| LWS450×1800 | 450 | 4 | 2800 | 2195 | 30~37 | 7.5~11 | 4~25 | 2500 | 3320×1700×1130 |

| LWS500×2000 | 500 | 4 | 2800 | 1976 | 45~55 | 7.5~11 | 5~30 | 2800 | 3520×1800×1170 |

| LWS530×2120 | 530 | 4 | 2600 | 2006 | 55~75 | 11~18.5 | 5~40 | 3800 | 4490×1425×1690 |

| LWS600×2400 | 600 | 4 | 2400 | 1935 | 75~90 | 15~18.5 | 6~45 | 4500 | 5090×1300×1650 |

| LWS650×2880 | 650 | 4 | 2400 | 1761 | 90~110 | 18.5~22 | 6~65 | 6000 | 5200×1550×1800 |

| LWS720×2880 | 720 | 4 | 2200 | 1612 | 110~160 | 22~30 | 70~110 | 8000 | 6100×1600×1800 |

More parts show of the decanter centrifuge:

Planet gear

Electric control cabinet

(Touch screen)Drum of decanter centrifuge

Productive process

Workshop

Company Profile

Our services As Follows:

Provide free technical training, guidance and information of accessories.

Our technical staff could instruct our customers on the installation of connector and accessories on site, and deal with technical and quality issues.

Once receive the customer complaints, we will response within 24 hours.

Free maintenance and replacement will be provided if defects result from quality failure of our product.

Our company will provide perfect after-sale services and technical support.

Contact person: Andy

Related Products

-

![Milk Cream Skimming Separator with High Efficiency]()

Milk Cream Skimming Separator with High Efficiency

-

![Iron Ore Gangue Rejection Wet Drum Permanent Magnetic Separator for Roughing]()

Iron Ore Gangue Rejection Wet Drum Permanent Magnetic Separator for Roughing

-

![Replacement Compair 100005424 Zs1063829 Screw Air Compressor Parts Oil Separator]()

Replacement Compair 100005424 Zs1063829 Screw Air Compressor Parts Oil Separator

-

![Chinese Manufacturer High Efficient Trommel Screen Waste Treatment Equipment Seperator for Recycling Line]()

Chinese Manufacturer High Efficient Trommel Screen Waste Treatment Equipment Seperator for Recycling Line